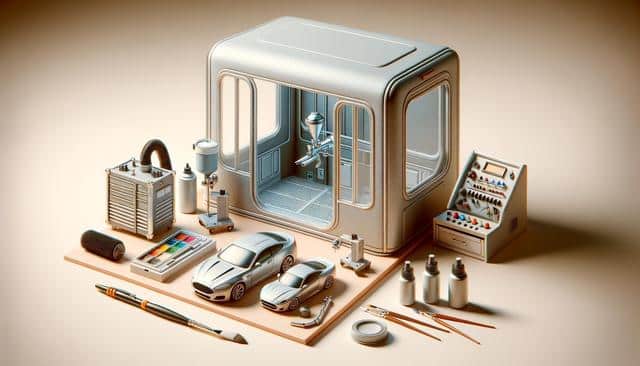

Looking for a Paint Booth? Expert Tips to Help You Choose the Right One for Your Budget

Choosing a paint booth can be overwhelming—this guide simplifies the process. Discover key factors like airflow types, filtration systems, and pricing to help you find the best fit for your budget and project needs. Whether for auto or industrial use, get the facts before you buy.

Understanding Different Types of Paint Booths

Before selecting a paint booth, it’s essential to understand the different types available and how each functions within a workspace. Paint booths vary based on their airflow patterns, size, and intended use. The most common types include downdraft, semi-downdraft, crossdraft, and side-draft booths. Each design offers distinct advantages depending on the application. For example, downdraft booths are often chosen for high-end finishes due to their efficient airflow, which helps reduce overspray and contaminants. Crossdraft booths, on the other hand, are more budget-friendly and easier to install, making them a practical choice for smaller shops or occasional use.

Key considerations when comparing types include:

- Airflow direction and control

- Ease of installation and maintenance

- Space requirements

- Ventilation and safety features

Understanding how each booth type aligns with your workflow and production volume will help narrow down your options effectively.

Airflow and Filtration: What You Need to Know

Airflow management and filtration are critical factors in optimizing painting results and maintaining a safe working environment. Airflow not only impacts paint quality but also operator safety by controlling the dispersion of fumes and overspray. Downdraft booths, for instance, pull air from the ceiling and exhaust it through the floor, offering superior control. Alternatively, crossdraft booths direct air from the front to the back, which may be sufficient for light or low-volume applications.

Equally important is the filtration system. A reliable filtration setup typically includes:

- Intake filters to remove dust and contaminants from incoming air

- Exhaust filters to capture overspray and airborne particles

- Optional pre-filters or HEPA filters for enhanced air purification

Choosing a booth with quality filters and appropriate airflow design helps ensure compliance with safety regulations and environmental standards, while also producing more consistent, professional finishes.

Budgeting and Cost Considerations

Cost is one of the most significant factors when choosing a paint booth, and understanding how pricing aligns with features can help you make an informed decision. Paint booths can range from a few thousand dollars for basic models to tens of thousands for more advanced systems with automated features. Your budget should reflect the intended use, frequency, and quality standards you need to meet.

When evaluating cost, consider the following:

- Initial purchase price

- Installation and setup expenses

- Maintenance and filter replacement costs

- Energy consumption and operational efficiency

Keep in mind that while lower-cost booths may suit occasional use, investing in a more durable, feature-rich model could offer better long-term value for frequent or professional applications.

Space, Size, and Installation Requirements

The dimensions of your workspace will significantly impact the type of booth you can install. Paint booths come in various sizes, from compact models suitable for small parts to larger units designed for vehicles or industrial components. It’s crucial to measure your available space and ensure the booth you choose fits both the physical and ventilation requirements of your facility.

Important space-related considerations include:

- Ceiling height and floor space

- Access doors and clearance for moving items in and out

- Ventilation pathways and exhaust locations

- Electrical and fire suppression system compatibility

Proper planning during installation can prevent costly modifications later. Many manufacturers offer modular designs or customization options to better suit your layout, which can be a cost-effective way to optimize your setup without compromising functionality.

Additional Features and Compliance Standards

Beyond the basic structure, many paint booths offer additional features that enhance productivity, safety, and compliance. These may include digital controls, temperature regulation systems, lighting upgrades, or integrated bake cycles for faster curing times. While these features can raise the price, they often improve overall workflow efficiency and output quality.

Also, ensure that any booth you consider meets local and national compliance standards, including:

- OSHA safety regulations

- NFPA fire codes

- EPA environmental guidelines

Some models are designed with certification in mind, making it easier to pass inspections and maintain operational legitimacy. Choosing a compliant paint booth not only protects your business legally but also ensures a safer work environment for your team.

Conclusion: Make an Informed Choice That Aligns with Your Goals

Choosing the right paint booth involves more than just comparing prices—it’s about aligning your purchase with your specific needs, whether that’s occasional hobby work or industrial-scale production. By understanding the different airflow systems, filtration options, installation requirements, and additional features, you can confidently select a booth that fits both your workspace and your budget. Take the time to evaluate your long-term goals and operational demands before making a decision, and you’ll be better positioned to invest in a solution that delivers reliable performance over time.